Our technology

What defines the Steiner brand?

Built for the toughest conditions

The proven STEINER lenses and prisms are installed in a rubber-armoured, indestructible, glass-fibre reinforced polycarbonate or magnesium die-cast binocular housing. The telescopic sights also consist of a seamless tubular body. Sealed and nitrogen-filled, the devices are now waterproof, impact-resistant and immune to other extremes. Now & Forever.

High user comfort

Due to their ergonomic design, the binoculars are safe and non-tiring in the hand; The rubber armouring with the ergonomically valuable ribs, curves and pads typical of STEINER ensures a non-slip and secure hold. The scopes have adjustable lighting, oversized turrets, silent, intuitive operation and the best repeatability.

You have not accepted content of Youtube currently.

Just see better

Steiner-Optik in Bayreuth has been setting standards in the field of premium optics for over 70 years. The more than 460 demanding manufacturing steps ensure the highest quality, from design to production. Continuous innovation creates technologies such as nitrogen filling, laser protection filters, Steiner Nano-Protection® and the typical Steiner high-transmission coatings such as the Diamond Marine coating. Constant user feedback from watersports to hunting to birdwatching keeps the performance standard at the top. For best optical quality.

Guaranteed Steiner

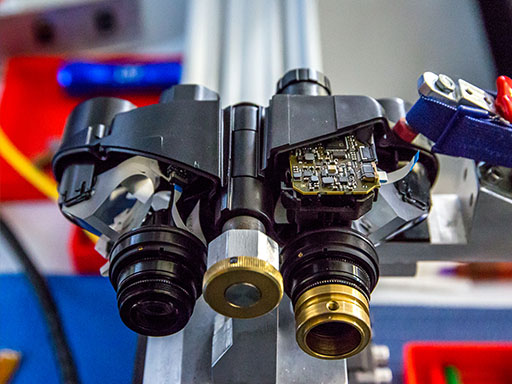

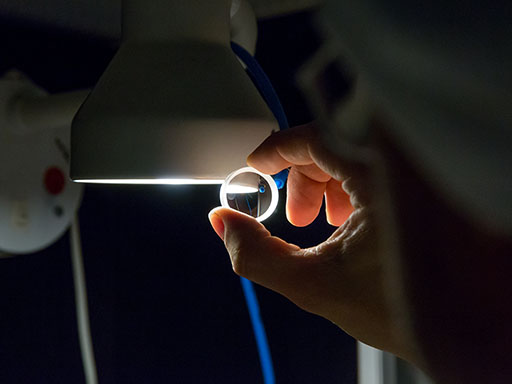

Steiner grinds and polishes the lenses and prisms himself, and the individual coatings that ensure brightness, contrast and high light transmission are applied to all air/glass surfaces himself.

100% Precision

In more than 460 high-precision manufacturing and control steps, the multi-coated optics and all other components are assembled in the polycarbonate or magnesium die-cast housing. Also, none of our binoculars leave production without being checked in quality assurance.

Perfect Compensation

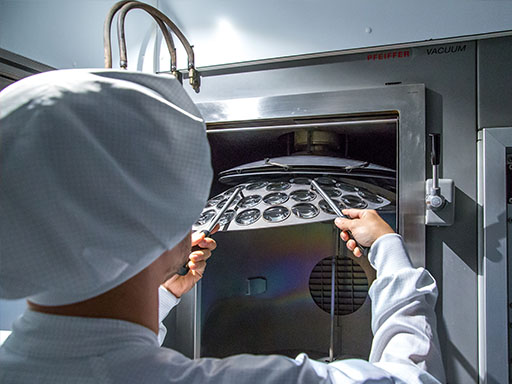

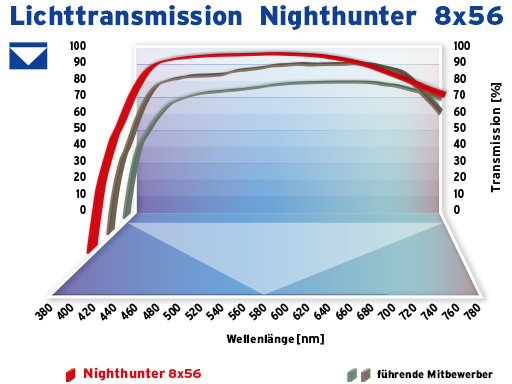

The coatings developed and vapor-deposited by Steiner were developed to increase light transmission, enhance contrast and deliver a sharp image, even under unfavorable lighting conditions.

STEINER – rugged and reliable

The use of new high-tech materials sets new standards for optical performance and robustness. Thanks to decades of user experience in more than 80 countries in the military sector, which is also reflected in our civilian products, we can say that Steiner manufactures the most robust binoculars in the world. Every single glass goes through demanding quality controls. Tests such as collimation, shock resistance, water resistance and temperature resistance ensure that all our binoculars that leave the house can withstand any extreme situation.

World Class Compensation

Highly special coatings ensure first-class light transmission. The images are razor-sharp and of the highest contrast — right to the edge. The scattered light is reduced to a minimum. Even in poor lighting conditions or when darkness sets in, contours are always clear and clearly visible.

Steiner Nitrogen-Pressure-System

A fogging or the formation of condensation inside the binoculars is completely impossible with this proprietary high-tech solution. Even temperature fluctuations of up to -40 °C to +80 °C do not affect the functionality of a nitrogen-filled Steiner binocular. Thanks to the 2-way valve technology, the binoculars can be serviced at any time, even after many years.

More light, better image

All Steiner lenses are sourced from premium glass suppliers. The surfaces of the lenses are multi-coated. Innovative coatings made from rare fluorides and minerals maximize sharpness, color and resolution. This demand for the highest glass quality enables unsurpassed light transmission and consolidates Steiner's leading position on the world market.

Ready to use anywhere and anytime

The tried and tested Steiner binoculars with their robust construction have been developed for the toughest conditions. For example, the extremely tough glass-reinforced polycarbonate withstands oil, heat, cold, sun, salt water and even solvents. The seamless, nitrogen-filled tube body of the riflescopes is shockproof up to 900 G. All models are waterproof, many even water pressure-tight up to 10m, resistant to dust, dirt and moisture. In terms of water resistance, robustness and resilience, we therefore have a leading market position.